R & D

Development Items

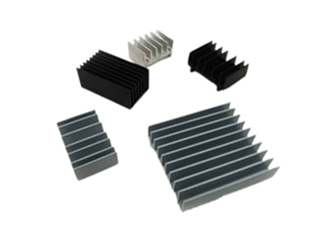

Thermal Conductivity Plastic

Thermal materials are used to effectively transfer or dissipate heat, helping control the temperature of products. They play a key role in managing excessive heat generated by electronic devices, automobiles, LED lighting, etc., preventing performance degradation or failure, and extending product lifespan.

Key Product Feature

| Applications | Electronics (CPU, GPU), LED Lighting, Automotive (Batteries, ECU, Motors), Aerospace and Defense Industries, etc. |

|---|---|

| Thermal Conductivity | 1 ~ 12W/mk |

| Heat Resistance | 110℃, 120℃, 200℃, 250℃ |

| Material | PP, PA, PPS |

| Surface Resistance | Insulation, Non-Insulation (E0~E5) |

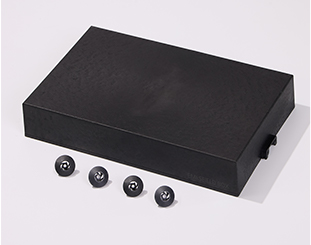

EMI Shield Material

Shielding materials are functional materials used to protect electronic devices from external electromagnetic interference (EMI), radio frequency interference (RFI), electrostatic discharge (ESD), or to prevent internal electromagnetic waves from leaking outside.

Key Product Feature

| Applications | Electronics (Smartphones, Laptops, Servers) Automotive (Electronic Components, EV Batteries) Medical Devices (MRI, CT) Communication Equipment (Routers, etc.) |

|---|---|

| EMI Shielding rate | 30 ~ 90dB |

| Heat Resistance | 120℃, 200℃, 220℃ |

| Material | PC + ABS, PC, PBT, PA |

| Surface Resistance | E-2 ~ E4 |

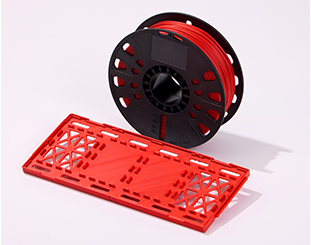

Biodegradable Plastic

With the increasing use of petrochemical products and stricter environmental regulations, there is a growing demand for the development of eco-friendly components to replace traditional petrochemical materials and parts.

Biodegradable plastics have been selected as an alternative material.

Key Product Feature

| Applications | Food Packaging, Disposable Containers, Agricultural Films, Medical Products, 3D Filament, etc. |

|---|---|

| Heat Resistance | 50℃, 80℃ |

| Material | PLA, PBAT, PLA, PHA |

| Surface Resistance | E8~E9 |